Call Us Today : +91 988420 0323 | Email : [email protected] |

Call Us Today : +91 988420 0323 | Email : [email protected] |

High Performance Manipulator Optimized For The Arc Welding. Collision Detection And Flex-servo Control. Robust Arm With Compact Wrist Design. All New Controller With Advanced Performance. All New Teach Pendant With Easier Operation. Better And Easier Maintenance. New Hardware And Software Realizing Advanced Performance. Digital Interfacing With Panasonic Full Digital Welding Machine Achieving Stable And Advanced Quality Welding Results.

Fully Digital Pulse Mig/Mag Welding Machines-ensures High Quality Ss/Ms Welding. High Performance Wire Feed Technology. High Performance Tig Equipment For Top Quality Welding. Thyristor Controlledac/Dc Pulse Tig Welding Machines. Igbt Controlled Dc Pulse Tig Welding Machines. Inverter Controlled Ac/Dc Pulse Tig Welding Machines. Thyristor Controlled Dc Arc Welding System.

Fully Digital Pulse Mig/Mag Welding Machines-ensures High Quality Ss/Ms Welding. High Performance Wire Feed Technology. High Performance Tig Equipment For Top Quality Welding. Thyristor Controlledac/Dc Pulse Tig Welding Machines. Igbt Controlled Dc Pulse Tig Welding Machines. Inverter Controlled Ac/Dc Pulse Tig Welding Machines. Thyristor Controlled Dc Arc Welding System.

Machines As Per The Welding Job And Requirement Of The Customer. With 2kva To 250kva Welding Transformers. With Secondary Feedback Controllers. With Plc Based Controllers. With Pneumatic Or Manual Operating System.

Machines As Per The Welding Job And Requirement Of The Customer. With 2kva To 250kva Welding Transformers. With Secondary Feedback Controllers. With Plc Based Controllers. With Pneumatic Or Manual Operating System.

CO2 Welding ROTORY WELDING SPM’S. Multi Stage Process Outputs. Plc Based System. Along With Welding Power Source

TIG Welding ROTORY/LINEAR WELDING SPM’S. PLC Based System. Along With Welding Power Source.

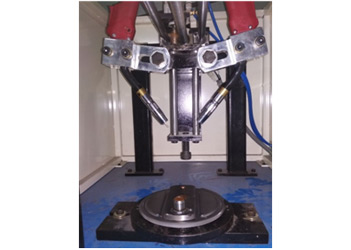

Multi Spot Welding Spm’s. With Multi Process Output And Linear Moving Units. PLC Based System. Along With Welding Controller.

CO2 Welding LINEAR WELDING SPM’S. Multi Stage Process Outputs. PLC Based System. Along With Welding Power Source.

Spot Rotory/Linear Welding Spm’s. PLC Based System. Along With Welding Power Source.

Multi Spot Welding SPM’S. With Multi Process Output And Linear Moving Units. PLC Based System. Along With Welding Controller.

Torch cleaning stations for Robotic/Automation Welding

Torch cleaning station is the complete solution for reliable automatic servicing of the torch head. Installed quickly and easily (Plug & Play), the compact torch cleaning station stands for top reliability.

Water cooling Units for Welding Systems

Type: CR 1250

Flow Rate: 7.0 lit/min

Tank Capacity : 15 lit

Cooling Capacity:1250W